Wicker Basket Of The Hotair Balloon

The basket is the lowest part of the balloon, just underneath the burner. The basket is the compartment that carries the propane gas tank, the pilot, the passengers and other vital instruments. Baskets come in a variety of shapes and sizes. Some are smaller for private flights, and others are larger for commercial flights. It is also possible to tailor-make the basket to a set specification, from the wall height and width.

Balloon basket structure

There are two main types of basket – open and T-partition. Open is when the fuel, the pilot, and the passengers are all housed together in just one compartment. T-partition is when the passengers are in one compartment and the canisters and the pilot in a different section in the basket. The T-partition has struts and is a stronger structure than the open basket. Also, the balloon remains more balanced overall with the T-partition as the weight is spread evenly over each compartment.

Balloon basket height

The average height of the basket is about 3 feet or 1 meter. The walls are high enough to feel very secure, as well as low-slung sufficiently for an adult to easily see over. Overall, the height of the basket is rarely in the way of the view.

Tremendous force exertion

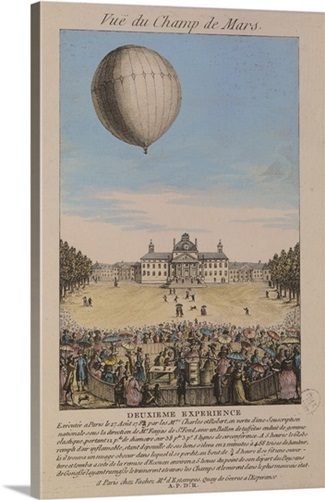

The basket is the most complicated structure because of the hard-core functions it must serve. During a flight, the basket is constantly on the move. It shifts from place to place swayed by the weather conditions. It also takes the pressure of the weight that it carries inside. Moreover, when the balloon lands it hits the floor and grinds to a halt. Therefore, both while in the air and on ground, the amount of force exertion on it is tremendous. Hence, the basket needs to be incredibly robust and be able to distribute any shock. That is why although there is an apparent evolution of a modern-day balloon from its invention of almost two centuries ago, the finest basket is still hand-made of wicker.

Made of wicker

Exploring the workings of an hotair balloon starts with examining the fascinating evolution of its basket where the passengers and pilot stand. The history of the basket is an old one that has not evolved much from the 19th century hotair balloon. And the reason why it has remained unchanged is due to a resilient material – the wicker. Despite the technological advancement and the innovation and availability of so many new synthetic materials, companies still use wicker to make the baskets. Wicker is the best due to its durability and flexibility. It absorbs much of the shock on landing any surface and doesn’t shatter upon impacting very hard surfaces or even in freezing temperatures. It is the best choice not only for impact-absorbency but also for strength and ease-of-repair as well as lightweight. Moreover, the wicker basket resists entanglement in power lines or branches. So, the story of a balloon basket must go hand-in-hand with explaining the inherent qualities and properties of wicker.

Qualities of wicker

The construction of the wicker basket consists of a tight, vertical weave around a stainless-steel frame that prevents it from falling apart. Most manufacturers pad the inside walls of the basket with either leather or suede for the comfort of the passengers. Outside is a urethane coating finish to resist becoming brittle. Besides, the coating ensures its longevity and protects the basket from rotting when exposed to dampness. The floor material is firm and beautiful giving the passenger stable footing and a strong sense of security. The inherent strength and beauty comes from a well thought out amalgamation of stainless steel framework, leather, wicker and foam padding.

Source of wicker

Wicker grows in Southeast Asia. Most baskets are woven from the finest quality cane Palembang or Kooboo as these are hardwearing, extremely sturdy and relatively lightweight. Companies use Round Reed only where color-dyeing is needed.

Notable basket companies

Enterprises that specialize in manufacturing balloon baskets have amassed decades of experience, knowledge, and skills in making them. Safety and comfort being the uppermost concern, they design the baskets using the premium ingredients that is available in the market. They are meant to last long and easy to maintain. Firefly and Lindstrand are two such companies that are well-known among the balloon adventurers, aviation enthusiasts, and hobbyists.

Firefly balloon basket

Known as the Cadillac of the hotair balloon, Firefly baskets are unique. They are aesthetically quite pleasing and easy to assemble without requiring any tools because all the components clip into place. The frame is woven in vertical pattern and colorful accents and padded with suede or smooth leather.

Lindstrand balloon basket

As leaders in the industry, Lindstrand has set the standard for luxury and quality. Each Lindstrand basket has a stainless-steel superstructure with a choice of either a woven or wooden floor. The frames are joined to solid nylon rod to assure that the basket will maintain its shape.

Wicker seats are resilient and lightweight, and this can enhance the fuel efficiency of even the wide-bodied aircrafts

Future of wicker

Perhaps what makes wicker a resilient material would be a good follow-up read or study. If the inherent properties of wicker can assure safety in the air, it warrants further study to see how to use them for practical applications on the ground. Wonder if anyone has thought of using them as passenger seats in an aircraft. Wicker seats are resilient and lightweight, and this can enhance the fuel efficiency of even the wide-bodied aircraft such as Boeing 747 or Airbus 380. It may be an idea well-worth considering. If not, we say wishful thinking and much bicker about wicker

5 Frequently Asked questions About Hot-Air Balloon Basket

To book a balloon safari, please fill out the following form or simply email us on safaris@safari-center.com