Travel To Kenya To Enjoy A Hot-Air Balloon Safari

Components

A basket, a burner and an envelope make up a hot-air balloon. People have been using these same three parts for hot-air balloon ever since the 18th century. Although the level is higher now, people still make it using just those three things. However, advancement has enabled it to fly higher, faster and safer.

Travel to Kenya to enjoy a hot-air balloon safari

1) Basket

The workings of hot-air balloon starts with probing the growth of its basket. It is the lowest part of the balloon and hangs beneath the burner. It carries the propane gas tank, the pilot, the people and other vital tools. Basket is the most complex structure because of the hard-core functions it serves. It is always on the move during a flight and shifts from place to place due to the weather. When balloon lands, it hits the floor and grinds to a halt. It also takes the pressure of the weight that it carries inside. Therefore, there is a lot of force exerted on it both while in the air and on ground. That is why the basket of a hot-air balloon needs to be robust and be able to absorb any shock.

Types of baskets

Baskets come in a variety of shapes and sizes. Smaller ones are for private flights. Bigger ones are for commercial flights and are usually rectangle in shape carrying up to 24 people at a time, split into slots, giving everyone a view. They have loading volumes. They last up to 800 flying hours. It can be tailor-made to set terms, from the height and width, with or without seat belts, padding and floor etc.

Structure

Two main types of basket are open and T-shaped. In an open basket, the fuel, the pilot and the people are all housed together in a single slot. In a T-shape, the people are in one part and the pilot in the other. T-shape basket has struts and is a stronger structure than the open basket. Also, the balloon balances itself overall with T-shape because the each part spreads the weight evenly.

Height

The height of the basket is about 3 feet. The walls are high enough to feel very secure, as well as low-slung enough for an adult to easily see over. In other words, its height is rarely in the way of the view.

Wicker

People make balloon baskets with wicker. They grow it in Southeast Asia. Firms weave most balloon baskets with the finest cane as they are hardwearing, sturdy, lightweight and easy to repair. Firms only use round reed when they need to colour-dyeing it. Despite the readiness of so many new things, wicker is still better than all of them due to its litheness, toughness and impact-absorbency. Moreover, wicker basket resists messy power lines or branches. That is why, although a modern-day balloon has evolved, they still make the basket with wicker.

Construction

Companies make the baskets base-first using plywood. Then they build a frame of cane on top of this plywood base. Then stainless steel wires walls the corner. Around the frame, they weave the wicker straight leaving holes in the body for straps that prevents the basket from falling apart. They then coat it with varnish to set the cane and to resist going brittle. These coatings also ensure protection from rotting when exposed to dampness. They sew the edges using rawhide, suede or leather. Most people pad the inside walls of basket for the comfort. Floor is firm and pretty giving the people a stable footing and a strong sense of safety. This strong and light framework can withstand any pressure. The strength comes from the union of wicker, stainless-steel framework, leather and foam padding. Solid stainless-steel cables or chains connect the basket to the burner, which they linked it above by robust, load-bearing tapes that run up its seams between its crown and throat.

Basket firms

Firms that make balloon baskets have amassed decades of practice, knowledge and skill in making them. Firefly and Lindstrand are two such companies that are well-known among aviation people and hobbyists. Firefly baskets are unique and are the Cadillac of hot-air balloons. They are pleasing and one can put it together easily without needing any tools as all parts clip into place. Then they weave the frame in straight patterns and accents. But, Linstrand is the leader that has set the level for comfort and value. But, safety and comfort being the most concern, both the firms design baskets using top level items. They last long and are easy to maintain.

Travel to Kenya to enjoy a hot-air balloon safari

2) Burner

The pilot uses wind to ascend and descend as well as to control the vessel’s motion once aloft. And burner is the tool that he or she uses to control it. It is the unit that makes and propels hot air. That is why burner is the engine of the balloon. Air does not escape from the bottom hole of the balloon because hot air always rises. In other words, lightness keeps the balloon moving up. Most balloons have extra burners for faulty controls or dirty fuel.

Fuel

Early balloons burnt straw and spirits for fuel. A vexing problem with that was leaking seals in the valves. By 1900, people have replaced these. Today, people use propane to operate hot-air balloons. It is cheap, stable, certain and always in stock. A usual flight that lasts an hour consumes about 30 gallons of propane. The fuel stores in stainless-steel tanks. Stainless-steel tanks are less cheaper than aluminium, but they are lighter and carries more fuel. But, since it does not have an odour, when it leaks, the pilot cannot spot it. So, as a safety measure, people add mercaptan, which has a strong scent, so that leaks are obvious through smell.

Firing up

To draw fuel, the pilot pulls a trigger on the burner valve. The trigger is like the knob on a stove or gas grill. When the pilot pulls the trigger, propane flows under pressure from the tank through the coils to the burner. The pilot carries a flint or a lighter to light or to relight as needed. It assures access to heat when needed. The burner only uses one fuel tank at a time. When the pilot-light ignites the burner, the flame heats up the propane along with the round metal tubing. This changes propane from liquid to gas. In other words, it turns the liquid gas to vapour. Propane in gas form makes for a strong flame and able fuel usage. It sends a seven-foot flame into the balloon. Hot air then propels direct into the balloon through the bottom opening. Once aloft, the pilot keeps firing the burner at constant times that helps to maintain standard warmth and height thereby keeping the balloon stable. The pilot can add heat for more lift, or let it cool to land.

Extra

Sometimes a 2nd propane valve opens up that burns liquid propane instead of gas propane making a weaker and less able flame. In Kenya, pilots often use this 2nd valve because it is much calmer than burning gas and can thus keep from scaring wildlife away. There is 1 other method by which heat goes to the balloon. It is by using a valve or cruise which allows for a standard heat by watching the exact flow of propane. It aids the pilot to maintain a straight flight without having to use the blast pipe. This would be like flying a hot-air balloon on auto pilot.

Types of burners

There are many types of burners subject to the balloon size. They are single, double, triple and quad design. People use single systems for smaller flights that carry 1 or 2 people. Double burners or dual systems have 2 burners and are the most famous. The triple have 3 burners and quad systems use 4 burners. They give a much stronger and more able flame. Trade flights use more robust systems and come equipped with a highly sturdy gimbal block system that the pilots adjust to their own needs. More modern burners are there for bigger balloons. Burners also come in many styles and designs, added with a range of air worthy frames. They are also custom-built for risky sports athletes who might want to break records.

Advanced burners

Since its start in the 18th century, there has been much progress in burners. It now yields high class designs with higher power, lower noise and a feature-rich design. People also make burners to one’s exact needs because of the progress in tools. These days people even make ultra-quiet flame systems or make them from their preferred type of stuffs. It also burns cleanly with less amount of condensation. Apart from that, a high class burner is easy to assemble and maintain without the use of tools, all at a reduced cost.

Burner firms

Lindstrand and Safire are the two balloon burner firms. Lindstrand jet stream burner has a single mono bloc body that has all burner controls, valves, fluids and pressure. It also stables heat as propane gas flows through the body before coming through the jets. Moreover, the valves contain various seals giving highest reliability on every flight. Safire burner started at Bristol balloon fiesta in 2013 and is already working for some of the leading balloon firm’s fleets. Since its start, it has offered the highest safety and value as well as less overall care. The novel features of Safire burner make it ideal for tourist places such as Kenya.

Buyer’s choices

Balloon buffs and fans look for many things when buying a burner for their hot-air balloons. Apart from things such as means to burn calmly and to work over a broad range of fuel pressures, the most needy feature of burner is the reliability of power output. But there are also many other options that cater to their unique needs. Thanks to cutting-edge tools, it is even possible to tailor-make them.

Travel to Kenya to enjoy a hot-air balloon safari

3) Envelope

Two most important parts of balloon envelope are its fabric and vents. The volume goes by the cube of its width and the area by its square. Envelopes range in size from 77,000 to 600,000 c. ft. It can expect to last 350 flying hours. The tool by which envelope works is rather complex.

Shape

Envelope shape has gone through a number of progress stages. At the time of making it, the load ring in the mouth used to form an acorn squash shape as a result of usual stresses as well as many internal forces and height. Also, more things in width area ended up in loose wrinkles and less things ended up in dents or tight spots. A large lightly loaded one will be very fat with a flat top and an obtuse angled bottom. Full-length load tapes gave it a bulbous gore or a pumpkin shape. In the end, the load ring died, and this ended up in the current shape. Today, the standard shapes are sphere and teardrop. These shapes need the least amount of heat and can climb faster. Any other shape makes it too tough to deflate and inflate in some windy days.

Advertisement

Some companies use unique design envelopes for advertising purposes. They apply slogan or brand names using acrylic paint or adhesive letters. Also, they integrate artwork into the style of the envelope. It is a technique that adds detail and colour to the shapes within any panel. Both processes are very complex and demanding.

Fabric

In the early days, people used a variety of materials such as rubber, paper, silk and plastic to make balloon envelopes. However, they make the modern fabric using either nylon or polyester. They are the lightest and the strongest materials that can take a tremendous amount of tension and heat. Fabric is usually brightly panels of different colours, patterns and designs. They test, maintain and regulate it well within safe operating procedures. Both has its advantages and disadvantages.

Advantages and disadvantages

Polyester fabric is more resistant against overheating and degrades very slowly, meaning when subjected to high temperatures there is no risk of a decrease in strength. Another advantage is that it has a slower color tone decrease. Also, polyester fabric is immune to moisture so that they can pack wet envelope for a lot longer without any smell. However, the disadvantages of polyester are that it is harder to dye and bends less compared to nylon fabric. Advantages of nylon are elasticity, durability of coatings and stronger rip resistance. But it needs protection from moisture because the dampness breeds microorganisms leading to reduced strength and increased permeability. A side effect is the odour if it is damp. The truth of the matter is that neither of them is superior in all.

Fabric seam construction

Fabric seam construction is critical to the durability and airworthiness of envelope. It supports the weight and minimizes pressure, prolonging its useful life. Most manufacturers make it by weaving panels of fabric between load tapes. They cut the boards at particular angles. They sew it together tightly at the seams to make an air-tight and leak-free container. The cords and load tapes are also sewn in. Load tapes carry the entire strain, and panels keep the air inside. Whether done by industrial sewing machine or hand, the construction features double lap seam i.e. two parallel rows of eight stitches per inch. Most manufacturers preferred this because of its strength and lightness.

Fabric sealant coating

After stitching the envelope, they coat it on the inside with sealant, most commonly with silicon or polyurethane to contain air and reduce porosity. Silicone-coated fabric lasts longer than polyurethane but is harder to work with because it is very slippery. They apply the coat mechanically under pressure. The number of layers depends on material fragility and air tightness. The coating also has an ultraviolet stopper that helps the fabric withstand sunrays.

Vents

Balloon envelope has openings at the top and bottom called vents, which help in steering and maneuvering the flight by controlling the temperature inside the envelope. Some balloons have turning or maneuvering vents on the sides. When the pilot lets out air through these side vents the balloon rotates 360 degrees providing the passengers a panoramic view. Once the pilot releases it, the vent automatically closes.

Crown

Top opening is the crown which collects most of the heat. It is particularly useful while landing. Two important parts of the crown are panel and parachute. The pilot pulls down a cord out of a hole via pulleys that opens the parachute through which hot air escapes and that is how the balloon descends. Temperature indicators are inside and near the top of the balloon. They are white at the time of installation, but if the air inside exceeds a certain temperature they turn black, which indicates that the balloon needs repair.

Skirt

Bottom opening of the envelope is the skirt, which is a flame-resistant material to stop it from burning or melting. Its peelable tapes help in containing hot air. It acts as a stovepipe when the burner is running, channeling the hot air straight up into the envelope and improving fuel efficiency by deflecting any wind on windy days.

Drag rope

Every envelope has a long heavy rope trailing it which slows down the horizontal and vertical speed in landing operations. If the pilot aborts the landing, he or she uses it to recover automatically. It was Charles Green, the English aeronaut Drag, who first used it in 1830.

Rip panel

At the moment of landing, the pilot quickly pulls open the rip panel. It is a section at the top of the envelope that is in place lightly. It adds greatly to the safety by making quick deflation possible. Rip panel was first used on April 27th, 1839 by John Wise, the American aeronaut.

Envelope companies

Kubicek and Schroeder are the two renowned balloon companies that specialize in envelope manufacture. However, Kubicek is the only hot-air balloon company in the world that invents and produces its own fabric. They have complete control of its production. Their envelopes are made of either nylon or polyester. The company recommends polyester because of long lifetime cycle that offers a standard warranty of 300 flight hours. However, polyester tends to be heavier than nylon. Moreover, dyeing and coating are simpler with nylon than polyester. But Kubicek has invested in a state-of-the-art production line that weaves and coats its fabric. The fabric of the envelope can be coated or uncoated.

Travel to Kenya to enjoy a hot-air balloon safari

Other ballooning gear

Balloon pilots have tremendous amount of control over the balloon’s rise, altitude, steering, descend and landing which they monitor with various instruments using anticipation skills developed over time. During the flight, the pilot is always studying the altitude, pressure, temperature and many other aspects. Such remarkable flight control is made possible with superior weather monitoring, radio or satellite communication and global positioning system as well as various other instruments that facilitate and support its functioning. These are equipment that they use frequently, some of which are mandatory but certain others are only recommended or optional. The various instruments used during the flight are a fascinating study in itself.

Altimeter

To know the altitude of the balloon flight, the pilot sometimes uses an altimeter. It can tell how high above the ground or sea level the balloon is when the ascent is taking place.

Variometer

At certain altitudes, it is hard to judge whether the flight is on the way up or down. The variometer is a rate-of-climb panel that helps gauge whether it is moving up or down and also measures vertical speed in feet per second or minute.

Pyrometer

An electrical sensor near the crown sends information about air temperature in a particular area.

Electronic ignition

Similar to an electric blast valve, an electronic ignition keeps the pilot light going and it operates off a battery.

Sparkler

A sparkler comes in handy as a jumpstart when the pilot-light inadvertently goes out.

Fuel gauge

The instrument that shows the amount of propane available is known as fuel gauge.

Electric blast valve

Almost all balloons have a valve control push-button that the pilot can operate from anywhere.

First aid kit

Most crafts carry a first aid kit that includes silver compound medication for burns.

Fire extinguisher

It is often recommended to have a fire extinguisher onboard to combat any propane-fueled fire mishaps.

Protective clothing

A few simple precautions such as protective device-goggles and heavy-duty gloves can go a long way in avoiding minor injuries.

Headgear

Protective hats are vital safeguards during fast or bouncy landing, and it is highly advisable to have enough of them onboard.

Logbook

The pilot maintains a logbook onboard to register date, place and pertinent details of every one of the flights.

Balloon pilot

Piloting takes skill because it is a spur-of-the-moment operation to a large extent. Balloon pilots have in-depth knowledge about a balloon flight. They are usually delighted and very generous in sharing information about the workings of a balloon flight. A license is a must for any pilot to fly a balloon. They earn it after flying for a number of hours, passing a verbal test as well as a flight test and making a solo flight with an examiner.

What hot-air balloonists need to know

Many adventurous people are enthusiastic about flying or owning a hot-air balloon and venture out to grab the best do-it-yourself kit. These DIY kits may provide the essential information needed to make and operate a hot-air balloon but leave out subtle nuances that could be crucial. For example, people wonder why the large size. They are large because the balloon needs hot air with a temperature of at least 120°C and radius of 4m to lift an adult’s weight. Those who didn’t know that would opt for a smaller size which may not perform in the desired manner. And there are many other pieces of information and clues one needs to consider when indulging in creating a balloon.

Readymade or tailormade

Some balloon enthusiasts prefer tailormade hot-air balloon while some others go for readymade balloon. For readymade balloons, the task is simply to pick one off the shelf. But for tailormade balloons, more information and details are needed on the part of the buyer. A hot-air balloon that is tailormade to each one’s specification and choice is an incredibly personal representation of personality, style, image, performance and more. There are limitless possibilities between the very simple to the most sophisticated design. Standard models can serve as a reasonable starting point. But the most important consideration is what purpose would the hot-air balloon serve. The second is, what fabric should go into the envelope. Price of a tailormade hot-air balloon varies considerably depending on the design and materials chosen. Desired options such as turning apertures, skirt, scoop, nomex etc. factors in the pricing determination. For these reasons, manufacturers quote its cost on an ad hoc basis. The essential facts and standard information available in DIY kits can go a long way in making an informed decision about hot-air balloon purchase. That way the user or operator would be in a much better position to choose the best option available.

Travel to Kenya to enjoy a hot-air balloon safari

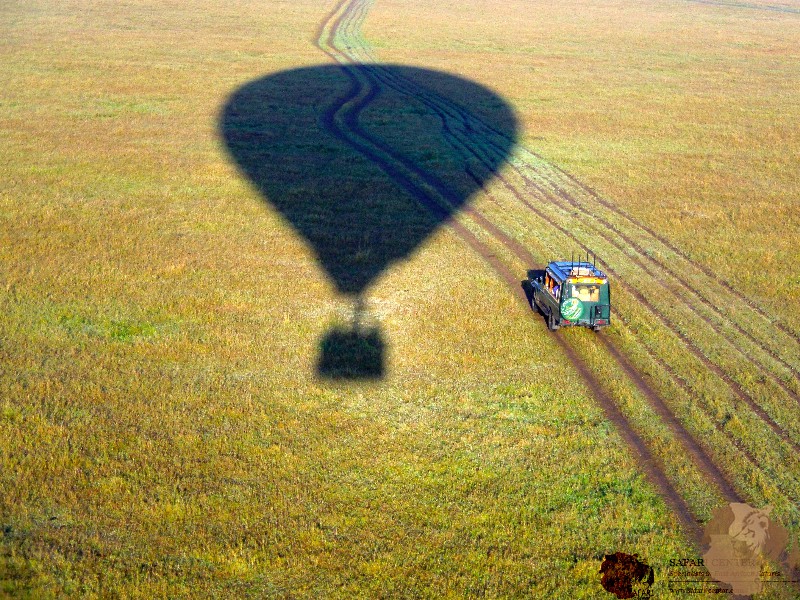

Balloon safari in Kenya

Travel to Kenya. Anyone who takes a hot-air balloon safari in the savannahs of Kenya marvels at the wonderful experience they feel while in the air, which lingers even after the ride. The flight starts with unpacking the basket, the burner and the envelope from the carrying bag. A typical hot-air balloon ride lasts for about an hour. Weather conditions are best just after sunrise and two hours before sunset because light winds often occur during these timings making for easier ascent and descent. It is the best time when one can avoid vertical air currents caused by heating on the ground that makes it harder to control the balloon. In between those times, when the sun is at its zenith, thermals make ballooning hazardous. The launch and ground crew spend much of the time inflating and deflating the balloon just before and after the flight. Duties of ground crew include launch preparation, following in the chase vehicle, getting permission for flight landing and keeping clear of spectators. Some passengers find the preparation that goes before and after the ride, i.e. inflating and deflating the balloon, more spectacular than the actual flight. The two things passengers who get onboard a hot-air balloon in Kenya have to pay attention to are to have one eye for the wildlife roaming the savannahs and the other eye for how the pilot maneuvers the craft. Other attractive aspects of the flight include lack of any feeling of movement and the exceptional quiet. Passengers feel absolutely no wind because the balloon moves with it.

1) Inflating

Travel to Kenya to enjoy a hot-air balloon safari. Once the crew has found an appropriate launching site, they mount the burner on a suspension concentration ring that connects to a metal frame on top of the basket. Then the bottom of the envelope is attached on top of the burner. The rest of the balloon is unwrapped and laid out on the ground, and the crew partially inflates it with cold air using a large, powerful portable fan. A ground staff stationed opposite the mouth of the envelope holds a rope tied to the top and prevents it from excessive sway until it is sufficiently buoyant. When there is enough air, they remove the fan and blast the burner flame into the envelope, which heats the air inside. The pressure starts building up, and that inflates the balloon all the way to an upright position. Meanwhile, the basket is attached to a vehicle on the ground, which holds it steady downwind to prevent it from rolling. At this point, the pilot steps into the basket to make pre-flight checks on rigging, operational lines, pulleys, velcro tables, parachute, flying wires and envelope fabric. Then the passengers climb into the basket as more heat is directed. With that additional heat, it becomes buoyant. When the launch crew sets everything up and ready, and the passengers are on board, the balloon is released. As the air heats up, the balloon gradually lifts right off the ground. This entire process takes about 30 minutes. The ground team then follows the balloon in a retrieve vehicle.

2) Rising

If the pilot wants to increase vertical speed and send the flight higher, he or she just has to increase the inside temperature by blasting a massive blaze rapidly. To decrease vertical speed, the air inside is let to contract by opening the parachute valve at the top of the balloon by means of a rope. When the pilot pulls it, some hot air escapes from the envelope, decreasing the temperature inside. It causes the ascent to slow down because less air is being displaced. Modern hot-air balloons have very large release vents at the top that can seal and unseal, which helps in changing its altitude. And that is how the pilot limits and controls vertical movement. Balloon altitude can range anywhere from treetop level to 5,000 feet. It can be adjusted within a matter of few feet by opening up a valve on the burner and letting the propane flow, which fires the flame into the envelope. However, the lift would depend on the basket weight as well as the temperature outside and inside the envelope. While ascending, the gas in the balloon expands, and the surrounding air’s density varies with altitude. If the atmosphere has a lower cooling rate, the climb speed of the balloon will bleed off the higher it rises. Therefore, cooler seasons provide lift at lower internal temperatures and thus allow for less propane usage. But, on the other hand, if the cooling rate of the atmosphere is high, the flight will accelerate. Therefore, hotter seasons need higher temperatures to achieve lift thereby using more propane. You need to travel to Kenya to enjoy a hot-air balloon safari.

3) Steering

The balloon is maneuvered horizontally by catching the wind draft at different altitudes. In other words, by adjusting the vertical position, the pilot catches different airstreams at various heights as desired. So, by adjusting the ascend and descend to the appropriate level and riding with the wind, the balloon can be moved to the desired direction. Speed would also depend on the wind at each altitude, which can be up to 120mph. Generally speaking, pilots don’t steer the balloons. Instead, a pilot’s job is to determine the wind direction and speed at each altitude and pick the most suitable one. Therefore, while aloft, the balloon’s horizontal cruise is at the mercy of the wind because its direction and speed are different at different altitudes. Being at the mercy of winds means leaving control to an external factor. Hence, navigating sideways is a hit-and-miss encounter. And that is what makes sweeping gracefully over the plains in a hot-air balloon a thing of joy. It is this aspect of power or the lack of it that is the hallmark of ballooning.

4) Wind direction

Pilots study the overall wind currents by obtaining a weather forecast report beforehand. Sometimes the pilot sends up a helium balloon to know which way the wind is blowing. Spitting or releasing a squirt of shaving cream can also indicate wind direction beneath the balloon. Visual clues include flags on poles, smoke from chimneys and watching other hot-air balloons. Good knowledge of aerology is the key to success when it comes to hot-air balloon navigation. Up to 30-degree difference in wind direction usually occurs in the first couple of thousand meters of altitude. No additional control is possible if there is only a stable and simple wind pattern.

5) Falling

Falling to the ground or descending is done by completely opening the parachute valve at the top so that hot air escapes and cold air rushes in. This reduces the internal temperature causing the balloon to land on the ground. The parachute valve is a circle of envelope fabric cut out in the upper part with a cord that runs down through the center. The pilot simply pulls the cord and opens the valve to let hot air escape.

6) Landing

Once airborne, the pilot is always searching for appropriate landing sites. It is very rarely possible to determine landing site beforehand since a balloon travels with the wind. For this reason, the ground crew follows the balloon by car to collect the passengers. The pilot communicates and discusses possible landing spots with the ground crew when it is time to land. The spot has to be broad and expansive with no power lines. When it lands, sometimes there is a skid or a bump, and the landing can be a little rough. The basket may occasionally tip over slightly. However, all of these are safe and reasonable. After a quiet hour in the clouds, people seem to enjoy this excitement. No amount of words can express the feeling unless one experiences it.

7) Deflating

Landing process consists of deflating and repacking the envelope. The ground crew at the landing site will hold the basket down once landed. Then the ground crew deflates the envelope, detaches it from the basket, folds it and packs it into a carrying bag. The basket and the burner are also separated and packed into the retrieve vehicle.

8) Breakfasting

The best and the fun part of the ride happens once the balloon is grounded. A luxurious champagne bush breakfast is served at the landing site in the wild as the ride ends. Ground crew is responsible for laying the table for this sumptuous first meal of the day. Maasai warriors who stand guard on all four sides keep their eyes wide open for any wild intruders. The sight of them around certainly does add to the ambiance of this bush experience.

Balloon companies

Balloon companies

The largest balloon manufacturers are Cameron balloons of Bristol and Lindstrand balloons of Oswestry in England. A close second is Aerostar International Inc. of South Dakota and is also the biggest manufacturer in North America. Other long-time balloon manufacturers are Balloon works of North Carolina and Head balloons of Georgia. But the innovators of eye-popping shaped balloons are Cameron Balloons as well as Thunder and Colt.

History

History

The history of how hot-air balloon came into being is indeed a spectacular story. But it is also perhaps the most untold nonfictional story in the history of humankind. Balloon building is a craft about centuries in the making. This unique flying craft was developed in the 18th century and is the oldest form of aviation. Pioneers in this industry are unsung heroes. Not many people paid attention to their daring ventures in the early days of aviation. Mentions of them in literature are few and far between. But giving credit where it is due is only appropriate.

Early days

Early days

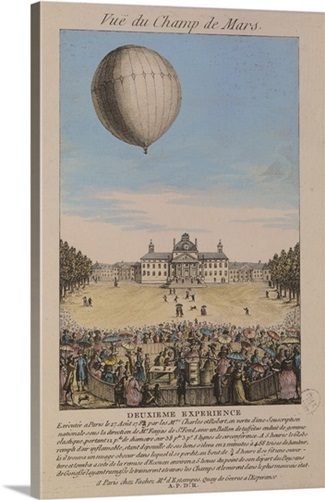

Hot-air ballooning was first popularized in 1863 when the French author Jules Verne published the novel Five weeks in a balloon. Subsequently, in the 1960s, US government tried to build and design them for getting military troops over the iron curtain. But balloons made too much noise and was not fit for it. In peacetime, they were used to take aerial photographs. But early days of aviation lacked access to technology and high-tech materials. Therefore, hot-air balloons could not be steered. Brave pioneers had to use pure ingenuity on a trial and error basis.

Montgolfiers

Credit for hot-air balloon invention goes to the French brothers, Jacques-Etienne and Joseph-Michel Montgolfier. They were prosperous paper manufacturers. Legend has it that the brothers took inspiration from watching the skirt of Joseph’s wife as it billowed from the heat of a kitchen burner that was being used to dry clothes. They also observed that heated air flowing directly into a bag made it rise. The bag rose because the air within was lighter than the surrounding atmosphere, which then pushed against the bottom. But the brothers thought that they had discovered a gas that was lighter than air when in fact it was merely air, which became buoyant as it was heated. Inspired by this, they made a crude envelope out of linen lined with paper. They then generated heat and smoke from fire and assembled them all together to create the first hot-air balloon. The brothers publicly demonstrated their invention before some dignitaries in Annonay, France on the 4th of June 1783. The 33-diameter balloon rose 6,600 feet and traveled about 2 kilometers. It stayed aloft for 10 minutes with nobody onboard. Little did they know that the age of ballooning began there as that was the first record of hot-air balloon flight.

Life aboard

As news of hot-air balloon spread, the Montgolfier brothers demonstrated one for King Louis XVI who proposed to test the effects of altitude on living beings. So, the Montgolfiers came up with the idea of suspending a basket below the balloon and sent it aloft on the 19th of September 1783 with three living beings – a sheep, a duck and a rooster to determine if living beings could survive at high altitudes. The sheep’s physiology is similar to humans. The duck was unlikely to be harmed. And the rooster did not fly at high altitudes. Hence, these three beings. The ride lasted 8 minutes and flew about 2 miles.

Manned flights

On the 21st of November 1783, Marquis d’Arlandes and Jean-Francois Pilatre de Rozier with special permission from the king of France made the first manned flight. The beautifully decorated, paper-lined cloth balloon with a fire grill attached to the base carried the two Frenchmen in a wicker basket. They went aloft over Paris for about 16km that lasted 20 minutes, and safely returned to earth. Witnessing this ascension were members of French Academy des Sciences, King Louis XVI and a crowd of 100,000 people including the American statesman and inventor Benjamin Franklin. It left a profound impression on the 18th-century world.

Sad endings

The launch of hot-air balloon brought to light their shortcomings. So, Jean-Francois Pilatre De Rozier created a craft with a combination of hydrogen and hot-air. Initial lift was provided by hydrogen, and subsequent flight control was provided by hot air. This way, the pilots didn’t have to release gas or drop ballast continuously. They coated the balloon with metallic gliding and artwork. Pierre-Jules Romain and De Rozier launched it from Boulogne on the 15th of June 1785. About 30 minutes into the flight, the coating produced static release and the envelope caught fire. Both of them died in that first balloon fatality. Ironically, de Rozier was not only the first passenger of balloon travel but also its first victim.

Tribute

The Montgolfier brothers continued with their experiments and went on to publish books on aeronautics during their careers for which they were honoured by the Académie des Sciences of France. Jacques-Etienne died on the 2nd of August 1799 after developing vellum manufacturing process. Joseph-Michel died on the 26th of June 1810 after inventing calorimeter and hydraulic ram. Ever since then, hot-air balloon has been continuously used for competitive sport, recreation, scientific exploration, marketing and trans-global adventures. The world commemorated the success of Montgolfier brothers after their time with illustrations and engravings of hot-air balloon on decorated chairs, crockery and clocks.

Buoyancy theory

Buoyancy theory

Hot-air balloon pioneers expounded on buoyancy theory while designing the craft. The theory was discovered by Greek mathematician Archimedes in 200 BC. Hence, this physical law is also called Archimedes theory of impetus. According to buoyancy theory, heated air is lighter because its molecules are less dense and has less mass per unit than ambient air. Consequently, it will go for elevation. So, warm air float on top of cold air. In other words, hot air rises and cold air falls. The upward resilient force is the same as the air weight that is displaced. It is the same theory that keeps food frozen in open freezers at grocery stores. It is the English scientist Tiberius Cavallo who demonstrated that it is possible for objects to rise and fall based on buoyancy theory. Hot-air balloons are essentially an original application of the fundamental scientific buoyancy theory or Archimedes principle. Heated air in the envelope weighs less than cooler air. Put in another way, expanded air inside the balloon is lighter than an equal volume of the surrounding air. Balloon rises due to displacement of air as well as the heat pressure trapped inside the envelope. Heated air exerts an upward force that defies gravity causing the balloon to rise and to stay in the air. Tiny changes in hot air in the balloon or the amount of ballast can control its buoyancy and make it ascend or descend. In violent maneuvers, great blasts of heat are required for a proper correction.

Types of hot-air balloon

Types of hot-air balloon

Montgolfier type is the most common balloon type. It uses fire to warm up the air inside the balloon to rise. The next is a hybrid category which uses hot air as well as a compartment of hydrogen or helium at the top. The third type is a gas balloon whose altitude can only be controlled by venting gas or dropping ballast. These three categories are utilized for different occasions depending on user’s needs. For instance, during International Gordon Bennett cup, pilots compete in gas balloons whereas for most long-distance records both hybrid and gas balloons are used as they require less fuel.

1) Hydrogen balloon

On the 27th of August 1783 Jacques-Alexander-Cesar Charles, the French inventor launched a hydrogen balloon. He then went on to design and build a larger hydrogen balloon with the help of Anne-Jean and Marie-Noel Robert. They included in it most of the features of a modern-day inflatable flight. On the 11th of December, Charles accompanied by Marie-Noel Robert made their first flight. On landing 36km away from Paris, Robert dropped off and Charles made the second trip. The aircraft took off and became the world’s first solo balloon flight.

2) Superpressure balloon

On the 3rd of December 1783, the French Gen. Jean Meusnier proposed the superpressure balloon that is kept under a constant volume. But it was not successfully built until sturdier materials became available. Polyester film with the highest tensile strength finally made it possible to develop superpressure balloons that did not expand or contract as the gas heats up or cools down during its operation. They are used by US National center for atmospheric research to carry instrumentation aloft that circumnavigates the earth for several months at a time.

3) Coal balloon

On the 19th of July 1821, Charles Green from London made the first coal balloon flight. Thereafter he made a celebrated flight on the 7th of November 1836 for 800km to Weilburg.

4) Stratospheric balloon

In 1905, Swiss Physicists Auguste Piccard and his twin brother Jean Piccard had devised a concept for diving ship. Based on that, they invented and launched the first successful stratospheric flight on the 27th of May 1931. It consisted of lightweight rubberized-cotton net-less envelope that was 14,000cu.m and a spherical aluminum pressure cabin. It carried Auguste and Pail Kipfer to a height of 15,781m. Their balloon had several new advances including a remote-control pyrotechnic ballasting system and blasting caps. On the 20th of November 1933 the US Navy Commander Thomas Settle broke the world-record by soaring in the same balloon to 18,665m. On the 23rd of October 1934, Jean Piccard and his wife ascended to a height of 17,550m with a slightly larger duplicate using magnesium-alloy cabin. It was followed by Capts. A Stevens and Orville Anderson flying at 22,065m on the 11th of November 1935 sponsored by US Army air corps and National geographic society. The rubberized-cotton balloon was 100,000cu. m and was named Explorer II. It was seven times the size of the one Piccard used, but still made of similar fabric.

5) Research balloon

After serious scientific balloon experiments in the late twentieth century, crewed balloon flights started conducting research in the stratosphere. These scientific research balloons can float and stay aloft in stable conditions for several days or even months and travel thousands of kilometers. They can also carry instrument payloads through the stratosphere’s upper reaches.

6) Latex balloon

Jean Piccard realized that the single cell had reached the zenith of its possible development. He postulated that with a cluster of small latex balloons that can carry light loads to greater heights, he could extend the limits of ballooning. Working with Thomas Johnson of Franklin institute, Jean Piccard developed a net-less film balloon and substituted conical skin for the suspension system. The payload was attached to the base of the cone. Piccard along with his students from University of Minnesota, including Robert Gilruth, flew it in 1937, carrying radio instrumentation and automatic ballast-releasing device. On the 18th of July 1937 he made a successful solo flight with 92 latex balloons. But the project was abandoned as there was little faith that it would work.

7) Smoke balloon

As parachutes were perfected, smoke balloons became popular for exhibitions and fairs. The standard grand climax of several celebrations during the early 20th century was a trapeze artist ascending below a black smoke belching balloon and then jumping back to earth in a parachute. As no fire was carried onboard, the smoke was essential to retain heat. Other types used are zero-pressure balloons, military tethered balloons, meteorological balloons and powered aircrafts.

8) Unmanned balloon

There is some speculation that unmanned balloons were first used by Chinese in the Shu Kingdom as airborne lanterns for military signaling. Unmanned balloons are also mentioned in the history of Nazca Indians of Peru who used it around 2,500 years ago as a tool for designing drawings in Nazca plains. In 1839, history saw the introduction of unmanned balloons for high-altitude investigations. Notable modern unmanned flight was that of John Wise’s 1859 launch of a balloon from Missouri to New York to test the air for a transatlantic flight. Also, unmanned flights carrying scientific research payloads of 2,500kg have reached above 42km altitudes with balloons as big as a million cubic meters.

9) Modern balloon

On the 22nd of October 1960, Ed Yost designed, built and flew the first modern balloon in Nebraska. In 1961, strong, lightweight and durable nylon fabric envelope was first publicized, which replaced plastic envelope. And kerosene was superseded by propane to heat the air. Later on, it adopted a rip panel as a venting system for advanced control and safety. Today, explorers and prize hunters use high-altitude balloons for extreme cruises over mountains and oceans to cross continents and even to circle the globe using a combination of hot-air and gas balloons. Modern day hot-air balloons are primarily used for recreation. And the primary objective of recreation ballooners is to break records. Hence, today, ballooning has become a competitive sport.

10) Sporty balloon

In 1925, Ralph Hazlett Upson developed an improved version of the balloon with exciting features for making record-breaking voyages. British businessman Richard Branson and his co-pilot Lindstrand in 1987 became the first people ever to cross Atlantic Ocean in a balloon. They also completed the longest flight on the 15th of January 1991 from Japan to Canada. A dozen years later, Bertrand Piccard and Brian Jones piloted the Breitling Orbiter 3 and flew around the world in a hot-air balloon for the first time. Steve Fossett from Australia beat that record in 2002 by circumnavigating the world in a balloon in just 13.5 days. And Dr. Vijaypat Singhania from India broke the previous record set by Per Lindstrand and achieved the highest altitude of 21,000 meters on the 26th of November 2005.

Unsuccessful attempts

Unsuccessful attempts

Balloons have not had much military use except at the time of war between France and Germany. Mail and people were carried in balloons from Paris railway stations whereas pigeons brought mail back. While coal was inexpensive and plentiful, expeditionary forces had logistic problems with producing hydrogen or transporting heavy compressed gas canisters. Subsequently, in 1903, Rev. John M Bacon developed and successfully tried a hot-air balloon in England using petroleum for gas. Bacon promoted the idea of performing military observations with the kind of balloons invented by him. But, although his trials were successful, he did not pursue it, and his work went unrecognized and unnoticed in the ballooning community.

Races

Races

Balloon races are more often than not an assessment of accuracy rather than speed. The ultimate aim is to hover closest to the target. Distance between the marker and the target determines the score. During some competitive flights, they will be required to approach 6 or more targets before landing. GPS units and topographic maps are used for navigation. Some experienced pilots can land in a precise location by taking a flight in one direction and catching the wind in the desired direction at a different altitude. On rare occasions, it is possible to return to the launch site, which is called a box effect.

Hazards

Hazards

Hazards of hot-air ballooning include mid-air collisions as well as excessive speed during landing. But colliding with high voltage power lines poses the greatest risk. The reason being that pilots prefer to land near the roads to reduce off-road driving that is essential to recover the balloon. But usually, power lines run along the streets. Hence, there is a high frequency of such incidents. Another risk is the strange aerodynamic performance encountered during aggressive climbs. Many pilots have reported experiencing a sudden reduced air resistance at vertical speeds, resulting in an unexpected acceleration. As of now, people have hardly any research to understand this phenomenon.

Trade organizations

Trade organizations

Founded in 1905 in France, the Federation aeronautique internationale is the nongovernmental organization that maintains records for both manned and unmanned flights for balloons, spacecraft, model aircraft, aerial vehicles and sporting events. Also, aeronautics agencies such as British balloon, Airship club and US Balloon federation maintain ballooning records. The US Federal aviation administration controls the operating criteria as well as the airworthiness and all countries follow suit with minor local variations.

Future

Ever since Montgolfiers’ crude balloon invention, the idea has been gaining momentum that eventually gave birth to a full-fledged aviation industry along which way history has witnessed some key moments. As a result, modern hot-air balloon is a far cry from the original design of the Montgolfiers. From the days of the naughty Montgolfier brothers of the 18th century who took inspiration from flying skirts to the modern-day balloon enthusiast Richard Branson, the industry has come a long way. Going forward, innovations centered around improving the burner and deflation system will continue to happen that will allow hot-air balloons to fly longer, higher and under more control. With that will come more options of models, sizes and styles to suit various needs and budgets.

To receive a colourful digibook about hot-air balloon with videos, images and text, please fill out the following form or simply email us on safaris@safari-center.com